FRP Bio Septic Tank Manufacturers in Chennai

The Rise of Leading FRP Bio Septic Tank Manufacturers in Chennai

Discover top FRP bio septic manufacturers in Chennai offering durable and eco-friendly solutions. Explore a range of advanced FRP bio septic tanks designed for efficient waste management and environmental sustainability. Contact us for expert guidance and high-quality products tailored to your needs.

Introduction to FRP Bio Septic Tanks

FRP bio septic tanks are innovative wastewater management solutions that are gaining popularity in Chennai due to their eco-friendly nature and long-term cost-effectiveness. These tanks are made of Fiberglass Reinforced Plastic (FRP which is a composite material known for its durability and resistance to corrosion Compared to traditional septic tanks, FRP bio septic tanks offer numerous benefits such as longer lifespan, minimal maintenance requirements, and higher efficiency in treating wastewater.

Growing Demand for FRP Bio Septic Tanks in Chennai

The increasing demand for FRP bio septic tanks in Chennai can be attributed to the growing environmental concerns regarding groundwater contamination. As the population density in Chennai rises, there is a greater need for sustainable wastewater management solutions to prevent pollution and health hazards. Government regulations supporting eco-friendly alternatives, along with the long-term cost-effectiveness of FRP bio septic tanks, have further fueled the shift towards these innovative systems.

Products

FRP Bio Septic Tank

- The Bio-Septic tank will have Five Compartments (Two Partitions), with interconnecting pipes. A common 600 mm Manhole is provided for the First & Second Compartment Inoculum to digest the human waste is added before using the bio-septic tank.

- Poly-grass lining is provided in the First Compartment to provide large surface area and for anchoring anaerobic bacteria in the inoculum.

- Bio-Media ( 400sq.m./cu.m.) is filled up to 50% volume in the Second Compartment to increase the surface area and serves as growth medium for the bacteria.

- The Third Compartment can be used for disinfecting the treated effluent by solar powered electro-chlorination. The tanks is 100% Leak Proof & easy to maintain. ‣ They can be buried underground and can withstand vehicle load over them.

- No Sludge Formation due to complete digestion of waste – hence periodic cleaning is eliminated.

- The system is available from 1,200 litres to 50,000 litres and usage member based design.

Technology

- The process of glass fibre filament winding is used for tank construction it’s high tensile strength resulting in high hoop tensile strength of the shell (250mpa). Product is tested as per AWWA D20 Standard

- To prevent deflection due to soil overburden and vehicle load the section modulus is increased by by increasing the thickness of the shell and the I/O ratio is reduced by providing the stiffeners.

- To counter buoyancy force (assuming empty tank and fully saturated soil) anchors are provided with nylon strap around the tank

- Made from homogenous type composite it never allows percolation of even moisture from earth to tank or tank to earth it is impervious

- Unlike thermoform resin like pvc or kdpe the polymerised the thermoset resin will not be affected by heat or weather condition

Our Tank specification

- The bio septic tank is an improved version of technology developed by DRDO Gwalior.

- It has five compartments with inter connecting flow

- The common man hole with cover is provided for the first tour compartments.

- Inoculum to digest human waste will be added before using the bio-septic tank.

- Poly-glass lining is provided in the first two compartments to provided large surface area and anchoring anaerobic bacteria in the inoculum

- Bio media (400 sq.m / cu.m ) is filled in the second and third compartments to increase the surface area and serve us growth medium for the bacteria

- The last compartment can be used for pumping and / or disinfecting in the treated effluent

- The can be buried underground and can with stand vehicle load over them.

- No sledge formation due to complete digestion of waste hence periodic cleaning is reduced.

Advantages

- impervious – no water seepage.

- No steeling construction resulting – no corrasion

- Overhead & aboveground tanks are protected from Uv trays

- Installation space by volume for composite tanks is hardly 5% more than water stored.

- It can be supplied with inside portions & required number of nozzles to meet the specific need of the clients.

- Eco-Friendly – Mimicking nature, our tanks use biological processes to break down waste, reducing environmental impact and pollution.

- Energy-Efficient – With self-sustaining processes, our tanks operate efficiently, lowering costs and carbon footprint..

- Cleaner Water – Advanced microbial systems ensure treated effluent is safe and cleaner, protecting aquatic ecosystems.

- Easy Replacement of Existing Septic Tank

- No need of slabs & supporting walls

- Less labour and easy handle

- Few hours installation and same day usage

- Affordable Price

- No Maintenance

- Kills Virus and Insects

- The Septic tank will not fill for life time

- 100% leak proof

- No formation of sludge

- Customize tank according to clients requirements

- Health Protection – Neutralizing pathogens safeguards public health, especially in regions prone to waterborne diseases.

| Capacity | Max.Outer Diameter | Max.Length | Users | ||

|---|---|---|---|---|---|

| Litres | Meters | Feet | Meters | Feet | In Numbers |

| 1200 | 1.00 | 3.28 | 1.90 | 6.23 | 8 |

| 1200 | 1.10 | 3.61 | 1.60 | 5.25 | 8 |

| 1500 | 1.00 | 3.28 | 2.55 | 8.3 | 10 |

| 1500 | 1.10 | 3.61 | 2.00 | 6.56 | 10 |

| 2000 | 1.10 | 3.61 | 2.70 | 8.86 | 13 |

| 2000 | 1.30 | 4.26 | 2.05 | 6.72 | 13 |

| 3000 | 1.30 | 4.26 | 2.95 | 9.68 | 20 |

| 3000 | 1.45 | 4.75 | 2.30 | 7.54 | 20 |

| 4000 | 1.30 | 4.26 | 3.85 | 12.63 | 27 |

| 4000 | 1.45 | 4.75 | 3.10 | 10.17 | 27 |

| 5000 | 1.30 | 4.26 | 4.70 | 15.42 | 33 |

| 5000 | 1.45 | 4.75 | 3.80 | 12.46 | 33 |

| 6000 | 1.45 | 4.75 | 4.50 | 14.76 | 40 |

| 8000 | 1.80 | 5.90 | 4.20 | 13.78 | 53 |

| 10000 | 1.80 | 5.90 | 5.20 | 17.06 | 67 |

| 12000 | 2.00 | 6.56 | 5.00 | 16.40 | 80 |

| 15000 | 2.00 | 6.56 | 6.20 | 20.34 | 100 |

| 20000 | 2.50 | 8.20 | 5.60 | 18.37 | 133 |

| 25000 | 2.50 | 8.20 | 6.90 | 22.63 | 167 |

| 30000 | 2.50 | 8.20 | 8.25 | 27.06 | 200 |

| 40000 | 2.50 | 8.20 | 10.83 | 35.53 | 267 |

| 45000 | 2.50 | 8.20 | 12.15 | 39.85 | 300 |

| 50000 | 2.50 | 8.20 | 13.46 | 44.17 | 333 |

| 50000 | 2.80 | 9.18 | 10.51 | 34.49 | 333 |

Top FRP Bio Septic Tank Manufacturers in Chennai

- With several years of experience in the industry, Global Bio Septic has established itself as a reliable provider of FRP bio septic tanks in Chennai.

- Their range of products caters to diverse customer needs, ensuring high-quality and efficient wastewater management solutions.

- Customer reviews and testimonials highlight the company’s commitment to excellence and customer satisfaction.

- Global Bio Septic stands out for its use of innovative technologies in manufacturing FRP bio septic tanks, ensuring superior performance and durability.

- The company holds certifications and accreditations, guaranteeing the highest standards of quality and reliability.

- Case studies showcasing successful installations demonstrate the effectiveness of their products in real-world scenarios.

- Global Bio Septic places a strong emphasis on sustainability initiatives and corporate social responsibility activities, aligning with the demand for eco-friendly solutions.

- Their after-sales service and maintenance plans ensure that customers receive ongoing support and assistance for their FRP bio septic tanks.

- With ambitious expansion plans and a focus on future prospects, Company C is poised to meet the evolving needs of the market in Chennai.

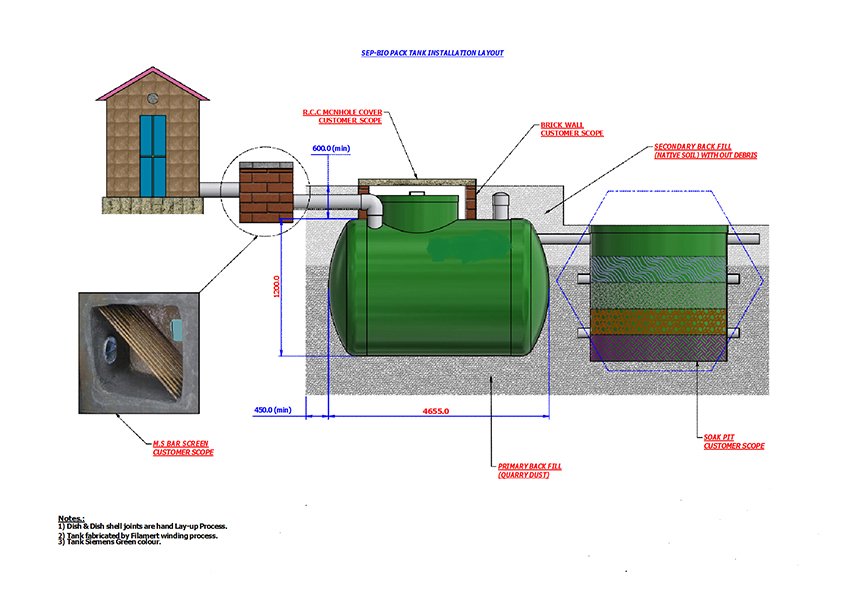

Installation Process and Maintenance of FRP Bio Septic Tanks

Site assessment and preparation

- Before installation, it is crucial to conduct a thorough site assessment to determine the most suitable location and size for the FRP bio septic tank.

- Factors such as soil type, groundwater levels, and proximity to water sources must be considered to ensure optimal performance.

- Obtaining permits and complying with legal requirements are essential steps in the installation process to avoid any regulatory issues.

Regular maintenance schedule

- Regular cleaning and desludging are necessary to maintain the efficiency of an FRP bio septic tank and prevent clogging or odors.

- Monitoring the system’s performance periodically helps in detecting any potential issues early on and addressing them promptly.

- Troubleshooting common problems like leaks or blockages should be done by professionals to ensure the longevity of the tank.

Benefits of Choosing FRP Bio Septic Tanks over Conventional Options

Durability and longevity

- FRP bio septic tanks are resistant to corrosion and rust, ensuring a longer lifespan compared to traditional materials.

- Minimal maintenance requirements translate to lower costs and fewer disruptions in the system’s operation.

- The durability of FRP materials makes them a sustainable choice for long-term wastewater management solutions.

Eco-friendly and sustainable solution

- By reducing environmental impact through efficient wastewater treatment, FRP bio septic tanks contribute to a healthier ecosystem.

- The energy-efficient operations of these tanks help in conserving resources and reducing carbon emissions.

- Recyclability and eco-conscious manufacturing practices make FRP bio septic tanks a sustainable option for environmentally-conscious consumers.

Cost-effectiveness and value for money

- While the initial investment in an FRP bio septic tank may be higher, the long-term savings in maintenance and repair costs make it a cost-effective choice.

- Considering the return on investment in the context of Chennai’s water management challenges, FRP bio septic tanks offer significant value.

- Affordable financing options further enhance the accessibility of these eco-friendly solutions to a wider audience.

Presenting bio septic tank non-filling sewage treatment solution. Easy, convenient and painless way of sewage disposal. No need to call lorry to clean your septic tank.

Bioseptictank is an advanced sewage treatment solution that uses Anaerobic Biodigestion Reactor Technology (ABRT) and undergoes five stage process to convert household sewage water into clear, odourless water. Treated water can be used for gardening or groundwater recharge. non-fillingbioseptic-tank provides you with an economic and environmentally friendly solution for wastewater treatment.

Large Internal Surface

Bio-septic tanks are designed with an intricate network of chambers and baffles, resulting in a significantly larger internal surface area. This ingenious design promotes the growth of beneficial microorganisms that efficiently break down organic matter present in sewage. As a result, the treatment process is accelerated, ensuring the conversion of waste into harmless byproducts more rapidly than traditional septic systems.

A Breath of Fresh Air

One of the most notable benefits of bio-septic tanks is their ability to eliminate foul odors associated with sewage treatment. The advanced microbial action within the tank efficiently digests waste, preventing the release of pungent gases that can permeate the surrounding environment. This not only creates a pleasant atmosphere but also reduces the potential for odor-related complaints from neighbors.

Kills Viruses and Insects

Bio-septic tanks are equipped with an inherent capability to combat harmful pathogens, including viruses and disease-carrying insects. The robust microbial ecosystem established within the tank acts as a natural barrier, effectively neutralizing potential health hazards. This feature is particularly advantageous in regions where waterborne diseases pose a significant risk.

100% Leak Proof

Traditional septic systems have a higher likelihood of leaks and seepage, which can contaminate groundwater and soil. In contrast, bio-septic tanks are designed with precision to ensure complete leak-proof functionality. The durable construction materials and meticulous engineering significantly reduce the chances of leakage, thus safeguarding the environment and public health.

No Maintenance

Maintaining conventional septic systems often requires frequent pumping and servicing to prevent system failures. Bio-septic tanks, however, demand minimal maintenance. The self-sustaining microbial ecosystem operates efficiently with little intervention. This not only reduces maintenance costs but also offers convenience and peace of mind to homeowners.

Light Weight

Bio-septic tanks are engineered using lightweight yet durable materials, making them easier to transport and install. Their compact design allows for simpler transportation to remote or challenging locations, making them a versatile solution for various geographical and infrastructural conditions

5 Stage Treatment

Maintaining conventional septic systems often requires frequent pumping and servicing to prevent system failures. Bio-septic tanks, however, demand minimal maintenance. The self-sustaining microbial ecosystem operates efficiently with little intervention. This not only reduces maintenance costs but also offers convenience and peace of mind to homeowners.

Summary

FRP bio septic tank manufacturers in Chennai are meeting the increasing demand for sustainable wastewater management solutions with innovative products and services. Companies like A, B, and C are leading the way in providing high-quality FRP bio septic tanks that offer durability, efficiency, and eco-friendliness. With proper installation and maintenance, these tanks provide a long-term solution for managing wastewater in residential and commercial settings.

FAQs:

Will there be any smell/odour?

When it flows from the outlet from the bio-septic tank to the soak-pit there will be no smell. However, if it is sprayed on a lawn with a pump from the last compartment of the tank there may be odour.

What will be the colour of water from the last tank?

After the 5 compartment treatment the effluent will be clear.

Do we have to pump out last tank water every day ?

The water from the last compartment will overflow into the soak-pit by gravity. There is no need to pump it out.

What will be the BOD in last tank?

The BOD will be 50 to 70 ppm in the last tank.

Do we have to pump out last tank water every day ?

The water from the last compartment will overflow into the soak-pit by gravity. There is no need to pump it out.

Any guarantee on process performance? We should not end up with buying a FRP tank after few days.

Normally 2 to 3 days is the recommended residence time for a 2 compartment septic tank treatment. Our bio-septic tank is designed for 6 days residence time and has 5 stage (compartment) design. Also, we provide poly-grass lining for the bacteria to adhere and grow and extended surface area with bio-media. If the system is not overloaded it should work without any problem.

What will be the feeding material for culture media? How much minimum water to be filled for getting proper results?

We supply only a start-up bacteria culture. The total system attains equilibrium in about 2 to 3 weeks. The culture can be added 10 to 15 days before the use of the bio-septic tank. 1 Kg. of culture can be added to 100 liters of water in the tank.

Media does it have any life and needs replacement after how many year’s?

No need to replace the inoculum. It will keep regenerating as long as the bio-septic tank is in use.

What happens to the sludge collected at the bottom. Will it be MLSS/MLVSS?

MLSS/MLVSS occurs only in aeration process. Ours is anaerobic process and hence the sludge is continuously digested.

Any odour pipe to be provided at height to disperse the odour of H2S gas?

We give provision for gas exhaust. However, unless absolutely necessary there is no need for a pipe to disperse the gases.

Any mosquito menace expected in future?

If the tank is kept sealed and the soak-pit is covered there will be no mosquito problem

Any precautions you recommend for getting good results from this septic tank.

- a) A bar-screen chamber is a must before the bio-septic tank to filter plastic and other non-digestible wastes.

- b) The system must not be overloaded.

- c) The soak-pit must absorb the effluents from the bio-septic tank. It should not be installed in high water table area.

Any media materials like sand, aggregate, carbon coils, coal etc to be filled? What is proportion of the same?

Nothing to be filled.

How is back wash done and back wash water quality parameters are they affect skin etc. Frequency of back wash.

No need for any back-wash

Remember, choosing an FRP bio septic tank can not only benefit you but also contribute towards a sustainable future for Chennai!